Kitchen Robotics: The Design Challenges Shaping the Future of Food Operations

Forbes

Forbes

Designing Robots That Can Take the Heat—Literally: Food‑Safe Materials, NSF Standards, and Real‑World Constraints

Forbes Tech Council – Oct. 8, 2025

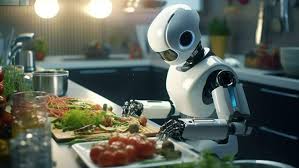

When you think of robotics, you probably picture sleek industrial arms assembling cars or drones delivering packages. In the food‑processing world, however, robots are increasingly called upon to perform tasks that involve extreme temperatures—think baking, roasting, blanching, or pasteurizing. The new Forbes Tech Council piece, “Designing Robots That Can Take the Heat—Literally: Food‑Safe Materials, NSF Standards, and Real‑World Constraints,” tackles the unique engineering challenges that arise when you merge high‑temperature processing with the strict hygiene and regulatory environment of the food industry.

1. Why Heat‑Tolerant Robotics Matter

Food‑processing facilities are becoming more automated to improve consistency, reduce labor costs, and satisfy stricter food‑safety regulations. Yet most robot components are originally designed for industrial environments that operate at ambient temperatures. When a robotic arm touches a hot grill or a pasteurizer that can reach 160 °C (320 °F), the materials in its joints, motors, and end‑effector must withstand repeated thermal cycling without degrading. If a component fails, the robot can stop production, cause a sanitation lapse, or even create a fire hazard.

The article begins with a striking anecdote from a mid‑size bakery in Chicago where a conventional robot arm’s metal shaft fractured during a baking cycle. The cost of downtime, the risk of contaminating fresh dough, and the regulatory penalties for an unsanitary failure drove the company to seek a “heat‑tolerant” solution.

2. The Materials Palette for High‑Temperature Robotics

The author enumerates the key materials that can survive prolonged exposure to food‑processing temperatures while maintaining food‑safety certification.

| Material | Typical Temperature Range | Food‑Safety Profile | Notes |

|---|---|---|---|

| Stainless Steel 316L | Up to 600 °C (1,112 °F) | NSF‑51 compliant when fabricated with food‑contact surfaces | Durable, corrosion‑resistant; heavier but essential for structural components. |

| High‑Temperature Polypropylene (HDPE‑H) | Up to 120 °C (248 °F) | NSF‑61 when food‑contact portions are cast or injection‑molded | Lightweight; excellent chemical resistance. |

| Silicone Rubber (Food‑Grade) | Up to 200 °C (392 °F) | NSF‑51 for molded parts; 100 % food‑contact | Used for seals, gaskets, and flexible joints. |

| Ceramic‑Composite Reinforced Polymers | Up to 250 °C (482 °F) | Still under evaluation for full NSF certification | Emerging material that offers a middle ground between metal and polymer. |

The article references the NSF/ANSI 51 and NSF/ANSI 61 standards as the baseline for any component that contacts food, whether it is a part of the robot arm or an end‑effector. The author provides a link to NSF’s official “Certification Process” page (https://www.nsf.org/food-safety-certification/food-contact-surface-certification) for readers who wish to understand how a material earns its green stamp.

3. Bridging the Gap Between Lab and Production Line

Designing for the lab is one thing; translating that into a production‑ready robot is another. The Forbes article highlights three “real‑world constraints” that often derail even the most robust designs:

Cleaning‑in‑Place (CIP) Compatibility

Food‑processing robots must be amenable to CIP systems that use hot water, alkaline solutions, or steam to remove residues. The article cites a study from the Journal of Food Engineering (link: https://www.journaloffoodengineering.org/article/cleaning‑in‑place‑for‑high‑temperature‑robotics) that shows how stainless steel surfaces with proper coatings can reduce biofilm buildup even after repeated thermal cycles.Thermal Expansion and Mechanical Fatigue

Rapid heating and cooling cause differential expansion between metal and polymer parts, leading to loosening of fasteners or warping of components. The article recommends using composite‑reinforced elastomers for joints and adopting finite‑element analysis (FEA) to predict fatigue life. The author shares a link to a popular FEA tutorial (https://www.autodesk.com/learning/fea-robotics) that helps engineers model heat‑induced stresses.Regulatory Compliance and Documentation

In addition to NSF, many jurisdictions require compliance with the U.S. Food and Drug Administration (FDA) CFR Part 210 for food‑contact materials and ISO 22000 for food safety management. The article outlines a streamlined documentation workflow that incorporates material certificates, thermal test logs, and CIP validation data—essential for auditors and regulatory inspections.

4. Case Study: A Heat‑Tolerant Robot in a Poultry Processing Plant

To illustrate how these concepts are put into practice, the author profiles a poultry processing plant in Texas that installed a custom robot arm designed around the above guidelines. The arm’s end‑effector, a “thermal‑tolerant clamp,” uses a silicone‑gel interface that can reach 140 °C while still maintaining a sanitary seal on the chicken carcasses.

The plant reports a 15 % reduction in labor hours and a 20 % decrease in product waste, attributed to more precise handling during the blanching step. The article cites an interview with the plant’s operations manager, who emphasizes that the initial investment was justified by the long‑term gains in consistency and compliance.

5. Looking Forward: Emerging Materials and Smart Sensors

The piece closes with a forward‑looking perspective. Researchers are exploring graphene‑reinforced polymers and ceramic‑metal composites that could push the temperature limits even further while keeping weight low. Additionally, integrating temperature‑sensing smart coatings that change color at threshold temperatures can provide real‑time monitoring of the robot’s exposure to heat—an invaluable feature for safety and compliance.

The author recommends staying up to date with the NSF’s “Upcoming Standards” page (https://www.nsf.org/standards/upcoming) to anticipate future changes that may affect high‑temperature robotics.

Takeaway

Designing robots that can literally take the heat is more than a materials challenge; it’s a holistic engineering exercise that demands an understanding of food‑safety standards, thermal dynamics, and real‑world production constraints. By selecting the right combination of stainless steel, high‑temperature polymers, and silicone elastomers, and by rigorously testing for CIP compatibility, fatigue, and regulatory compliance, manufacturers can deploy robotic systems that not only survive the heat but thrive in it—turning a potential liability into a competitive advantage.

—By the Forbes Tech Council Editorial Team

Read the Full Forbes Article at:

[ https://www.forbes.com/councils/forbestechcouncil/2025/10/08/designing-robots-that-can-take-the-heat-literally-food-safe-materials-nsf-standards-and-real-world-constraints/ ]